Soldier piles and lagging retains soil, using vertical steel piles with horizontal lagging. Whether an open or low headroom site, Keller has the equipment and experience to design and construct the optimal solution.

Common uses

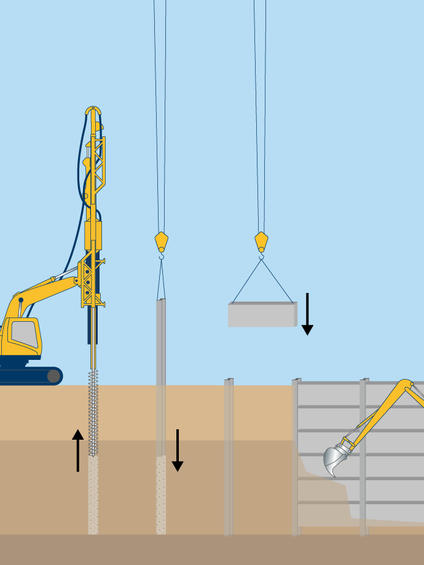

Process

Typically, H-piles are drilled or driven at regular intervals along the planned excavation perimeter. In low headroom or difficult drilling conditions, micropiles may be used. Lagging consisting of wood, steel, or precast concrete panels is inserted behind the front pile flanges as the excavation continues.

Additionally, contact lagging or shotcrete may be applied. The lagging efficiently resists the load of the retained soil and transfers it to the piles. The walls can be designed as cantilever walls or receive additional lateral support from anchors or bracing. They can also be designed as temporary or permanent walls when beams are coated and permanent wall facing is used.