Secant or tangent piles are columns constructed adjacent (tangent) or overlapping (secant) to form structural or cutoff walls. From soil mixing to drilled shafts, we draw on our complete suite of techniques to optimize the design and construction of these walls.

Common uses

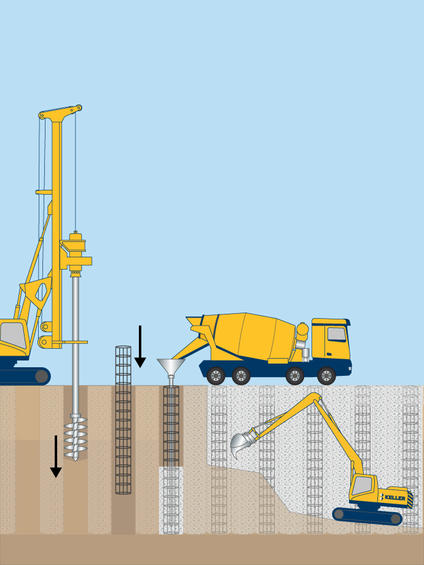

Process

The columns are constructed using soil mixing, jet grouting, auger cast, or drilled shaft methods. Sequenced construction of the elements helps ensure a tight seal for water cut-off. The design can incorporate steel bars or beams for reinforcement. Anchors provide additional lateral support if needed. Secant or tangent pile walls can be constructed in various soil conditions, including through cobbles and boulders.

Secant pile walls retained by anchors or strutting systems are often supported by a waler beam to distribute the loads (prevent punching of anchor/strut through the pile) and as a mitigation measure for the unlikely event of an anchor/strut not carrying the load. This waler beam can be constructed as a reinforced concrete beam cast towards the pile wall or using steel profiles to be fixed to the piles and anchors/strutting systems.

Advantages

Quality assurance

We use the latest technology, testing regimes, and best practices protocols developed over many years to ensure our pile walls' position, verticality, and structural integrity.