Jet Grouting uses high-velocity fluid jets to construct cemented soil of varying geometries in the ground.

Common uses

Process

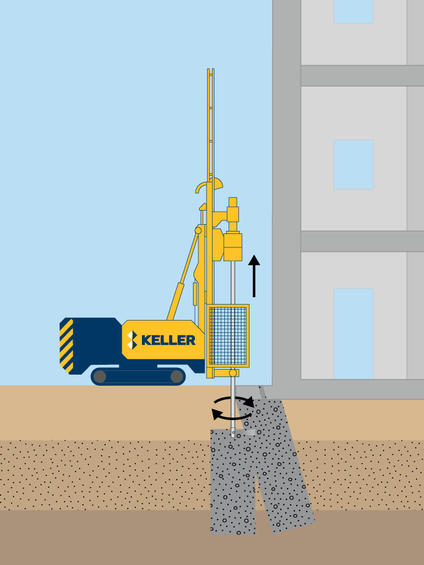

Jet grouting creates in situ geometries of soilcrete (grouted soil) using a grouting monitor attached to the end of a drill stem. The jet grout monitor is advanced to the maximum treatment depth. Then high-velocity jets (cement grout with optional water and air) are initiated from ports in the monitor. The jets erode and mix the in situ soil with grout as the drill stem and monitor is rotated and raised.

Depending on the application and types of soils, one of three variations is used: the single fluid system (slurry grout jet), the double fluid system (slurry grout jet surrounded by an air jet), and the triple fluid system (water jet surrounded by an air jet, with a separate grout port). The jet grouting process constructs soilcrete panels, full columns, or partial columns with designed strength and significant permeability.

The soilcrete geometry and physical properties are designed based on the in-situ soils. Because it is an erosion-based system, soil erodibility plays a major role in predicting geometry, quality, and production. Cohesionless soils are typically more erodible by jet grouting than cohesive soils.

Specialist contacts

Lucian Spiteri | Chief Grouting Engineer | 973-417-1667

Max Pucciarello | Senior Design Engineer | 973-897-4101

Advantages

Quality assurance

An in situ test program is generally installed before production to meet the project's intent and ensure that the jet grout program is successful. Based on a review of the project borings, the application, and previous project experience, initial jet grout parameters (or sets of parameters) are established and executed in the field for the test program. The test program will specifically demonstrate the jet grouted elements' column spacing, overlap, and geometry of the jet grouted elements. The test program will also verify the consistency of the grout batching, evaluate the equipment functionality, and confirm the real-time recording and reporting of the jet grout parameters. These processes establish a standardized protocol for each specific soil type that is consistent and repeatable for the production columns.

Keller’s proprietary data acquisition (DAQ) system enables us to continuously monitor and record specific jet grout parameters at the rig. The DAQ interface provides real-time information to the drill rig operator, while the column construction data is uploaded wirelessly to a server soon after completion for report generation. These reports can then be reviewed in near real-time by project management and submitted to the client.