Soils often need treatment to support the weight of a building or to withstand the loads imposed by a piece of infrastructure. This can mean ground improvement or installing foundations to transfer the loads to deeper, more competent layers.

Common Uses

- Increase bearing capacity

- Reduce settlement and permeability

- Mitigate liquefaction

- Increase slope stability

- Collapse / fill voids, stabilize mines / karst

- Accelerate settlement

- Treat expansive soils

- Stabilize soft ground

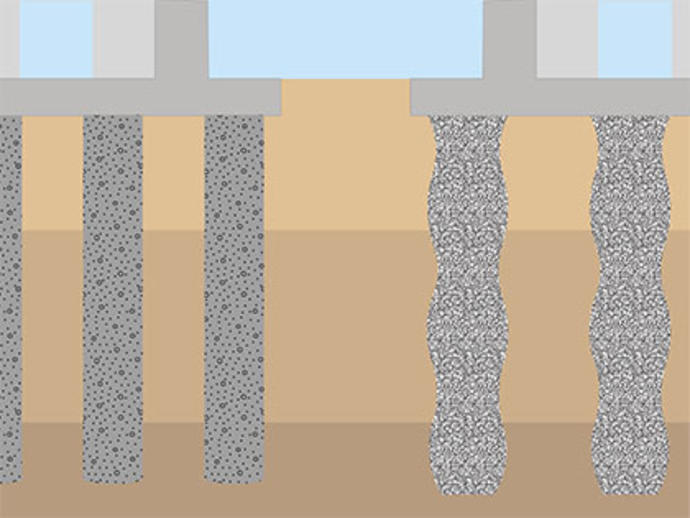

The mechanism of achieving ground improvement varies by technique and soil conditions. Densification using vibration or displacement is an effective means of improving granular soils. Reinforcement involves constructing or inserting stiff elements within a soil mass to create an improved composite material. Soil can be improved by adding cementitious materials, permeating granular soils, or mixing in all soil types. The insertion of vertical drains decreases the amount of time it takes soils to settle and strengthen when subjected to a surcharge load.

Voids can cause overlying structures to settle. Compaction grouting, cement grouting, polyurethane grouting, and other specialized grouting techniques permanently fill voids. Keller has experience with the full range of void-filling techniques to stop mine subsidence and stabilize sinkholes.

Heave due to expansive clay soils is a common problem in some areas of the US. Injection systems treat expansive clays beneath buildings and landfills with the pressure injection of an aqueous solution of water, lime or lime/fly ash slurry, or potassium chloride. Water injection pre-swells expansive clays before construction. Lime injection fills the desiccation pattern of expansive clay with slurry and stabilizes the pad's surface for workability for building pads, streets, parking lots, and runways. Lime/fly ash injection improves low-strength soils to improve the bearing capacity and/or trafficability of runways, landfills, and bridge approaches. Potassium chloride injection arrests heave occurring beneath existing structures by limiting the amount of water underlying clays can absorb. Keller has experience with the full range of ground improvement techniques.