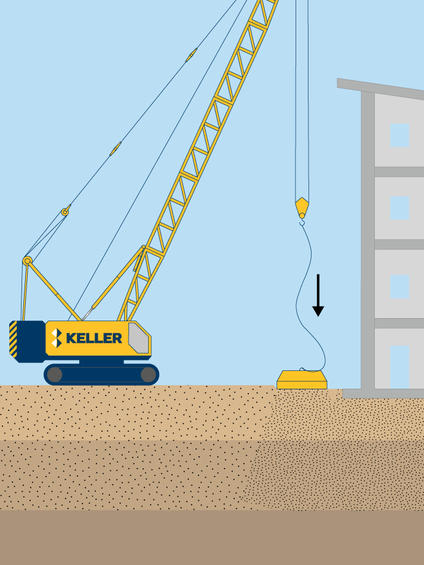

Dynamic compaction uses the energy from a falling weight in a pre-determined grid pattern to improve granular soils and fills.

Common uses

Process

Dynamic compaction is a ground improvement technique that densifies soils and fill materials using a drop weight. The drop weight, typically steel, is lifted by a crane and repeatedly dropped onto the ground surface. Vibrations transmitted below the surface improve soils at depth. The drop locations are typically located on a grid pattern, the spacing of which is determined by the subsurface conditions and foundation loading and geometry.

Treated granular soils and fills have increased density, friction angle, and stiffness. In shallow karst geologies, dynamic compaction has been used to collapse voids before construction to reduce sinkhole potential. It has also been used to compact construction debris, urban fill, and sanitary landfills before constructing parking lots, roadways, and embankments. The removal of compressible, contaminated fills can sometimes be avoided.

Advantages

Quality assurance

Typically, in situ testing by borehole or static cone penetrometer, allied with measurement of print volume and site surface settlement, is performed during the dynamic deep compaction.

The treatment pattern, energy level, number of passes, and phasing of passes must be designed to consider the soil conditions, type of development and required bearing capacity, and settlement characteristics. It is essential to thoroughly understand the soils before treatment and maintain close control during all phases of the work.