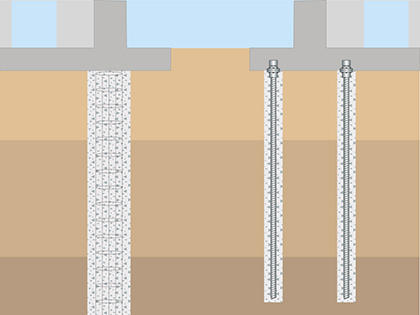

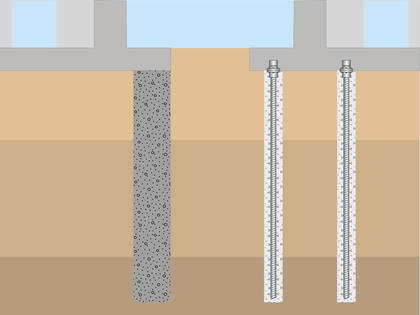

Deep foundations

Installing structural elements in weak soils to transfer loads.

Environmental remediation

Environmental remediation includes removing or containment of hazardous waste or subsurface contaminants.

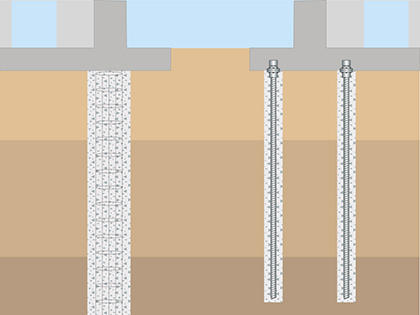

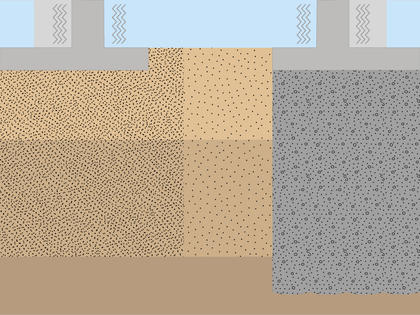

Ground improvement

Treating soils to support buildings or withstand loads.

Groundwater control

Controlling or preventing the movement of groundwater.

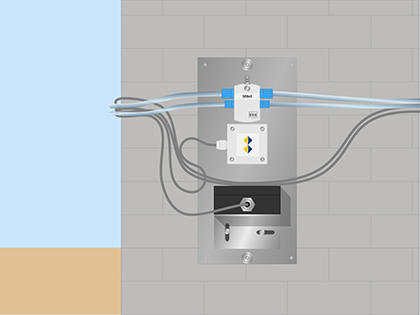

Instrumentation and monitoring

Monitoring structural or ground movement or environmental properties.

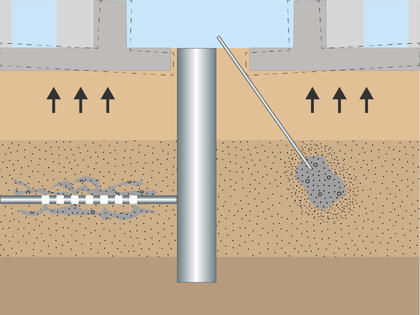

Liquefaction mitigation

In seismically active areas, improving loose, granular soils below the water table to protect from damage.

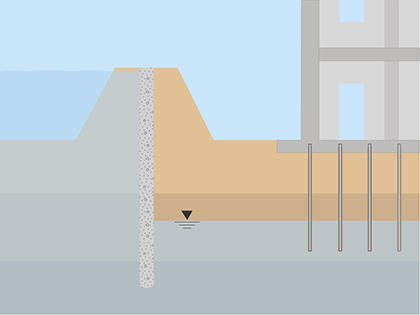

Releveling structures

Bringing buildings back to their correct level and strengthening the ground under foundations.

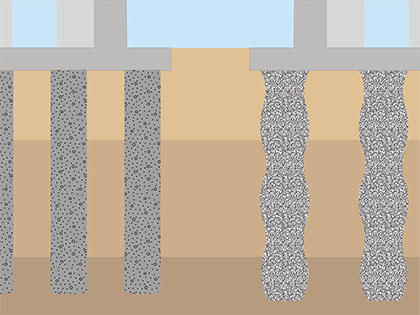

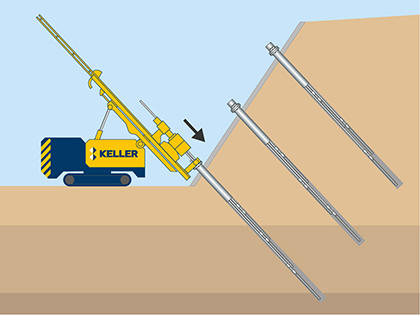

Slope stabilization

Retaining soil in slopes and excavations.

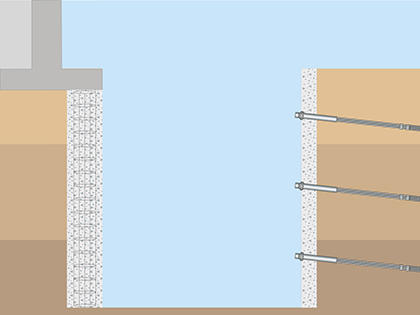

Support of excavation

Enabling stable excavation and preventing movement and damage to structures and utilities.

Underpinning